N

Nick_Karatzides

Guest

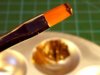

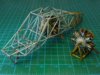

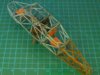

Once the base coat has cured, I brushed the oils with a broad, soft brush and spread the paint around until the desired colour density is achieved. Because working in oils is a little bit goes a long way, I started by putting just a little bit of paint on the end of the brush. I kept the brush strokes going in one direction and didn’t really worry about leaving brush strokes - I wanted them there for the wood grain. I tried not to spread it on too thick, or it would make the next step more difficult.

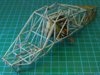

At this point the oils would be workable for several hours. With a broad, soft, clean and completely dry paint brush, I draged over the oil paint, leaving wood grain streaks. I jiggled the brush every now and then to give the grain a bit of variation. As the brush picked up the paint, I wiped it off on a clean, lint free cloth and continue process. “Lint free is the key phrase, as any speck of lint would adhere to the oil paint and destroy the finish. The beauty of this technique is that you can clean the oils off and try again if you goof up. Use a clean cloth and paint thinner (mineral spirits or turpenoid - not lacquer thinner) to wipe clean any mistakes and start over again. For the 1/18 scale Kolibri helicopter frame, it took me about two or three tries to get the paint density and colour right, but it really was quite painless.

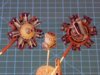

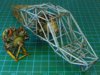

In some parts of the model which should look more bright, I slightly toned up with "Buff" & "Yellow Ochre" mixtures, or even pure “Basic Flesh Tone" and “Sunny Flesh Tone", while some others had to show darker, using "Brown" or "Raw Umber" color and blend naturally. Meanwhile, I tried same painting procedures on the wooden 3-steps ladder (used by Luftwaffe WWII ground crews and technician personnel for ground vehicle & aircraft maintenance procedures), which also got CAD designed & 3D printed with the helicopter kit parts to be used as a diorama accessory.

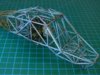

As soon as the result was OK for me, I left it alone to dry for few days and then sprayed over selected areas with Tamiya Color X-24 Clear Yellow acrylic, because it also helps bring the grain color out more.

At this point the oils would be workable for several hours. With a broad, soft, clean and completely dry paint brush, I draged over the oil paint, leaving wood grain streaks. I jiggled the brush every now and then to give the grain a bit of variation. As the brush picked up the paint, I wiped it off on a clean, lint free cloth and continue process. “Lint free is the key phrase, as any speck of lint would adhere to the oil paint and destroy the finish. The beauty of this technique is that you can clean the oils off and try again if you goof up. Use a clean cloth and paint thinner (mineral spirits or turpenoid - not lacquer thinner) to wipe clean any mistakes and start over again. For the 1/18 scale Kolibri helicopter frame, it took me about two or three tries to get the paint density and colour right, but it really was quite painless.

In some parts of the model which should look more bright, I slightly toned up with "Buff" & "Yellow Ochre" mixtures, or even pure “Basic Flesh Tone" and “Sunny Flesh Tone", while some others had to show darker, using "Brown" or "Raw Umber" color and blend naturally. Meanwhile, I tried same painting procedures on the wooden 3-steps ladder (used by Luftwaffe WWII ground crews and technician personnel for ground vehicle & aircraft maintenance procedures), which also got CAD designed & 3D printed with the helicopter kit parts to be used as a diorama accessory.

As soon as the result was OK for me, I left it alone to dry for few days and then sprayed over selected areas with Tamiya Color X-24 Clear Yellow acrylic, because it also helps bring the grain color out more.