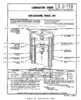

This dozer blade came in kit form and could be installed on any Sherman. They came two to a crate, an M1 and an M1A1 each per crate. The difference between a M1 and an M1A1 Dozer blade was pretty minor, and an M1A1 dozer blade was universal, but the M1 blade only worked on Shermans with VVSS. This is because the M1A1 blade was wider. Here is some data on the blades. The reason the wider blade worked on the narrower VVSS tanks was because the kit came with spacers to fill the gap left by the wider A1 blade when used on a VVSS tank.

Blade Data

Blade Height: —————————————————————————————-48 inches

Overall width M1:———————————————————————————124 inches

Overall width M1A1:——————————————————————————138 inches

Added weight to tank M1:————————————————————————-7100 lbs.

Added weight to tank M1A1:———————————————————————-7400 lbs.

Lift height of blade M1:———————————————————————18 to 30 inches

Lift height of blade M1A1:——————————————————————18 to 42 inches

Lift Load, M1:——————————————————————————————- 4000lbs

Lift Load M1A1:—————————————————————————————–5000lbs

The TM for the kit makes it sound like it was installed on tanks at the Depot Level and then the tank was issued to a unit with the blade kit installed and ready to go. After reading through the tech manual, it could be done by the tank crew without to much trouble, though a small crane would be nice for the installation of the hydraulic cylinder, but that seems like it would be a rare occurrence. If the kit had a drawback, it was that the blade blocked the bow Machine gun.

T

The kit broke down into several major parts groups.

Hydraulic Group:

Hydraulic Group: Was made up from external and internal parts that were a part of the Hydraulic system including the pump, an oil reservoir, and all the brackets to install these parts. There were also hoses and fasteners of various types. It also included a special wide angle periscope for the driver. Once

To install these parts a few things had to be removed from the interior. As this pictures show, the pump and tank assembly was fairly large. Essentially the tray for the spare periscope head box and the box had to be removed. The several brackets and guards had to be removed, and then the generator itself and its mount had to be pulled. It also involves disconnecting the transmission side of the propeller shaft, and installing a new pulley on it to run the hydraulic pump from. Once everything was installed, it did not impede the crew any more than when it wasn’t there since nothing took up the space right above the transmission.

A few parts from the hydraulic group did get installed outside the tank, the hydraulic hose, run through the left headlight mount. A guard for the hose and a cable running from a handle on the inside, used to jettison the blade in an emergency. All these parts are universal to all models of Sherman, though a few brackets could require a little modification for everything to fit right do to the way some hoses and belts were run.

The hydraulic jack and the framework attacking it to the tanks tow points on the front of the tank are also in the hydraulic group. There were several bracket sets for use with the different kinds of differential housing the tanks could have. There was a cover assembly/bracket to protect the mount, and hoses, and help position the jack

.

.

.

.

once you drill a few hole in the plaster.

once you drill a few hole in the plaster.