Thanks for the nice post, Andy.

Next up is the bomb bay.

This better shows the answer to Paul and Jim's question about rigidity of the port wing once the fuselage is ripped about.

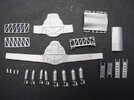

The kit supplies four bombs, two each side. There was plenty of room for more, so I doubled the amount to eight from my bits bag.

Here are the kit components for the bomb bay.......The walkway, right centre, is upside down.

View attachment 469652

View attachment 469652

First coat brushed on.

View attachment 469653

Here's the initial stage of the bomb bay...The walkway and the eight bombs fitted on their racks and glued between the two main spar bulkheads.

View attachment 469656

View attachment 469657

View attachment 469658

As a bonus, I'm learning more about the guts of a B-17G as I tackle each stage of this terrific kit from

Revell.

It might not be totally accurate, but such things don't bother me. I'll be adding bits as I go along. It's just a joy to build and am I having fun! That's

all that matters.

And at only £20 delivered, plenty of beer tokens to spend.

Cheers.

Ron

Though regardless of the method used, the end result you got to looks good, it should show off the interior very nicely.

Though regardless of the method used, the end result you got to looks good, it should show off the interior very nicely.